Quality Costs

One of the comments we get when speaking with customers is “That’s expensive!” or “I didn’t know that it cost so much!” And we totally understand where many people are coming from, in large part because they don’t work in the industry and don’t know what goes into everything we do. So, we thought we would pull back the curtain a bit and explain a bit why quality costs what it does.

The People

Designers

We hire talented people to work for us. Not to brag, but, okay wait, we’re going to go ahead and brag: both of our designers have BFAs in Graphic Design from Montana State University. When you’re a sophomore you’re required to submit a portfolio review to continue on towards the degree and you only have two chances to get through. If you fail, you have to wait five years to try again. Both of our designers made it through their first time.

Installers

Two of our three installers are 3M certified graphic installers. If that sounds fancy, it’s because it is! 3M certification means:

Our installers have superior installation knowledge and skills (which they had to prove via both a written and practical application exams)

Our business ethics have been reviewed and approved

We carry liability insurance (which protects your vehicles when you bring them in to get wrapped)

We only use the best quality vinyl

Our team also needs the requisite tools to carry out these installations and these are not the sort you can necessarily just find at a big box store.

Operations

Our operations manager and the other members of the team bring a wealth of experience to their roles. She has to keep track of our projects, client contacts, billing, etc. All of those have necessary and important monthly subscription software. The operations manager has to track everything from the initial inquiry to the finished project and those few minutes here and there add up to a lot.

The Process

Site Survey

If you’re in a 15-mile radius around Bozeman, Montana, we are going to come out to your site and assess the particulars of your project. That takes time with the customer, but also the driving to and fro.

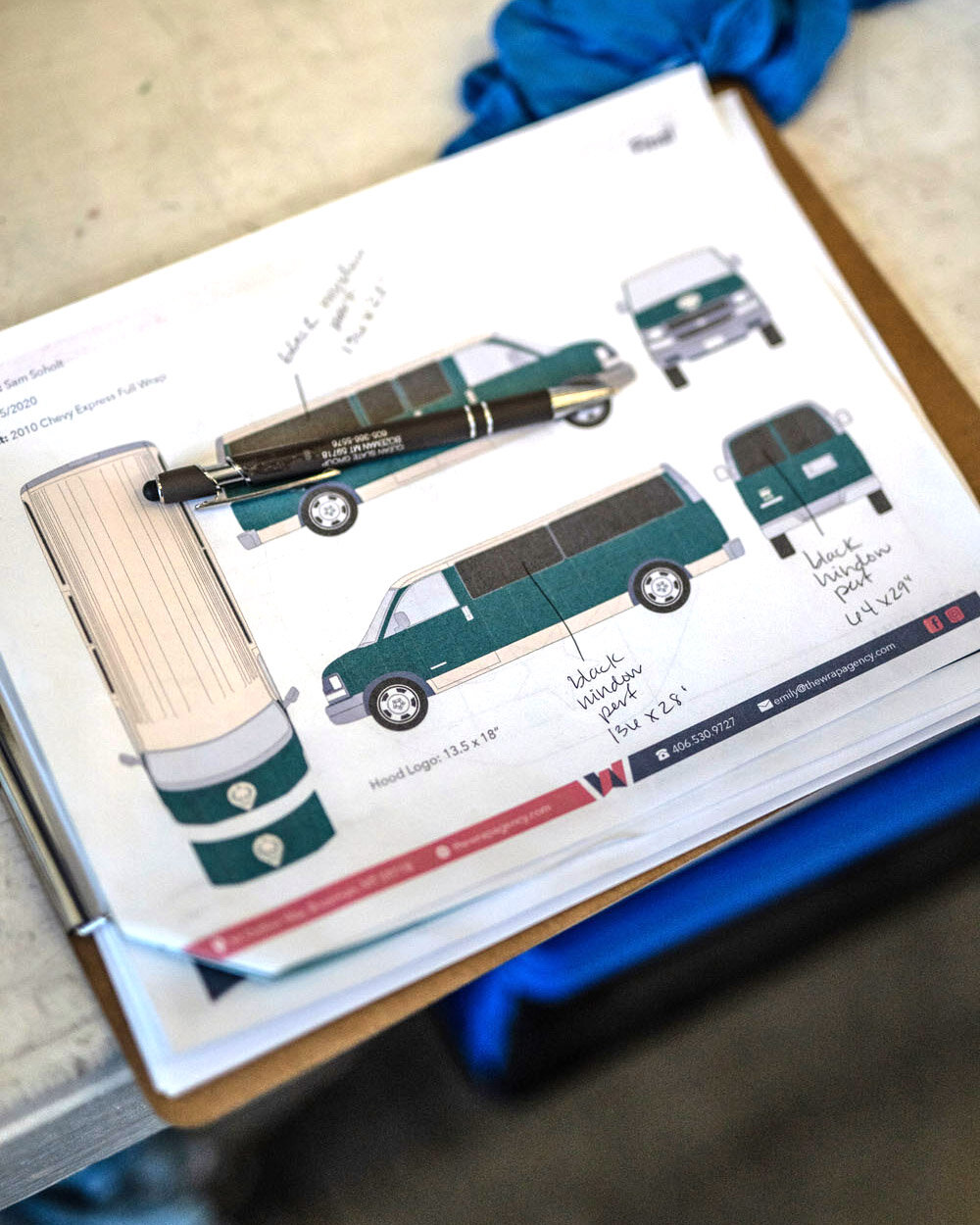

Design

That design work needs to be done on computers built for design work. We have three purpose-built Macs to do just that. We also have access to the best software and images available on the web, which comes at a monthly cost. We even have to have a subscription to a vehicles’ database so we can have exact measurements for our wraps (which saves us a lot of time). Whenever we do a custom job that isn’t a vehicle, we have to design those templates ourselves and that takes a measuring tape, patience, and a lot of time.

Photo by Sam Soholt

Production

The equipment and printers we use are expensive, but more importantly, they require skilled operators and careful handling and maintenance. They also require SPACE. You can’t run a production facility out of a small single car garage: you need space for all the equipment to operate efficiently (and to give your team members space to operate so they don’t have to crawl over or under things as part of routine work).

Installation

While some might visualize this part as a “peel and stick” process, it’s anything but. Before you do anything you have to clean and prep the surface. When it comes to vehicles, that prep can include disassembly (we might have to take out a tail-light on a vehicle or unscrew rivets on a trailer)

Photo by Sam Soholt

The Profit

Once we’ve taken care of these costs and paid all of our vendors and team members, we want to make a profit, not just so we can pay taxes and contribute to our local and state economy in that way, but so that we can re-invest in the business and grow it, and reach out to meet new customers that we can help.

So hopefully when you’ve had a chance to see things from our perspective by examining our quality costs, you can see why quality costs. If you want your work done in a timely manner, with thoughtful and intentional design, backed up by friendly and responsive customer service, we’re the team for you. No one else even comes close. And that’s not bragging, those are just the facts. :-)